There are two very important measurements of accuracy to consider when purchasing a torque wrench for highly specified threaded fastening applications in assembly.

- Full Scale (FS)

- Indicated Value (IV)

The differences between these two metrics are significant.

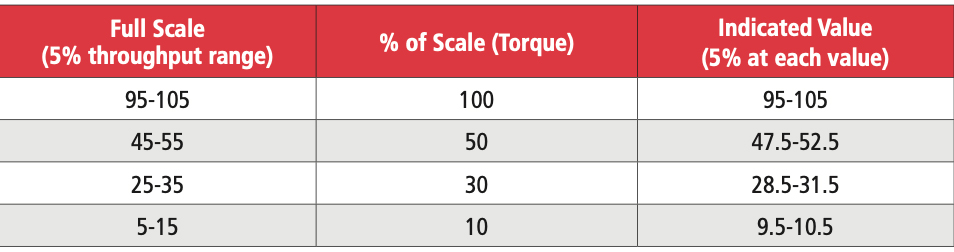

Full Scale (FS) accuracy measures the allowable error over the full-scale range of the tool. When utilizing Full Scale, the tolerance against the scale varies from 5% to 50% (based on a tool that is accurate to + or – 5%) because we’re looking at the full range of the tool.

Indicated Value (IV) measures the allowable error at the set point on the wrench. When utilizing Indicated Value the scale varies at 5% at each value rather than the full scale.

What this means is that Indicated Value (IV) wrenches are more accurate to the specified torque level of your application. This is especially true at the lower end of the torque range.

The table below shows the allowable tolerance for Full Scale vs. Indicated Value accuracy:

Still researching? This blog post entitled Click, Break or Slip? Picking the Right Torque Wrench covers the types of torque wrenches and can assist you in selecting the perfect wrench for your application.

Ready to make a torque wrench purchase? See our full line of torque wrenches to find a tool which will provide the consistent threaded fastening results you’ve become accustomed to receiving from ASG.

If you have any questions about a torque wrench purchase, or need further assistance, please contact ASG Customer Service at 888-486-6163 or [email protected].