In this installment we’re focusing on the different head styles and drive types most common to the precision fastening community at large.

First let’s pick things back up from where we left them in 1760 when Jesse Ramsden invented the first screw cutting lathe though. From this point in history, handheld screwdrivers first appeared around 1800. So while it is widely assumed the development of trade was the root cause of the industrial revolution from 1760-1820, we’d like to like to offer a more simple explanation:

We invented and built the tools which made the industrial revolution possible.

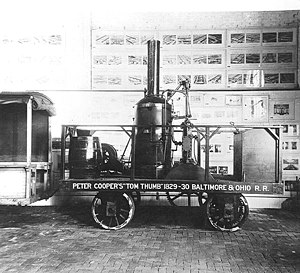

With those tools came the steam engine and the first railway trip of the locomotive in 1804 which opened up the entire country to use of these tools.

Fast-forward to 1961 and the first cordless power screwdrivers hit the market, as Martin Marietta Corporation contracted with a partner to design tools for NASA. Meaning the tools we built to make the industrial revolution possible, also made space travel possible.

Pretty cool, right!?

With that, let’s jump into the most common types of head styles and drive types on the market today!

Head Styles

NOTE: Many of these head styles are also known by their abbreviated terms in many circles. Flat head can be condensed down to FH, oval head to OH or OV, and so forth.

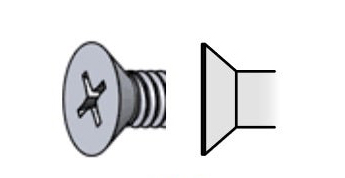

Flat Head | A flat head differentiates itself by having a countersunk head with a flat top. Since the head does not extend beyond the surface the tool sinks in into the fastener for a great connection. They’re most commonly made of stainless steel or zinc coating. |

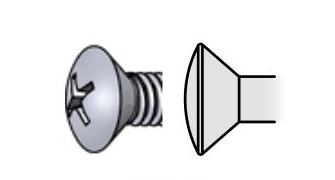

Oval Head | An oval head also includes a countersunk head, but the rounded top gives the head a more decorative finish. For this reason, they’re specifically used in higher traffic areas (think light switches) in which they’re seen often. |

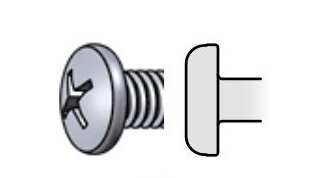

Pan Head | Our first non-countersunk entry, Pan heads offer a slightly rounded head with short vertical sides. The flat or domed top surface with a recessed socket is a favorite amongst wood screws, self-tapping & self-drilling screws as well as machine screws. |

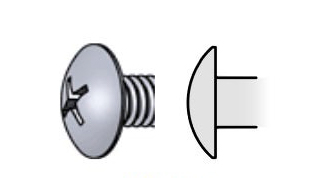

| Truss Head | A truss head combines a rounded top with a wider surface area just underneath the head. Wooden truss head screws are often used to attached cabinets to steel studs and in sliding shelving. The the low-profile nature of this head type lends itself to great use within guides. |

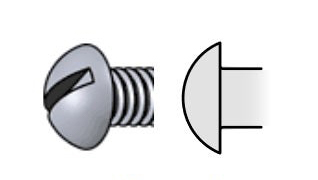

| Round Head | The rounded head screw takes a domed approach, and while it is less commonly used these days, this offers an additional option which can be seen as a viable alternative to the oval head above. |

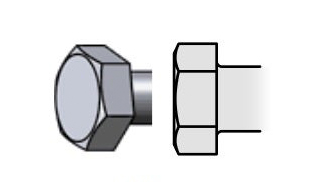

| Hex Head | A hexagonal head is a six-sided option which attaches with a wrench or socket and is closely associated with machine screws. That said, wood screws can also have a hexagonal head for applications which require higher torques to complete the fastening process. |

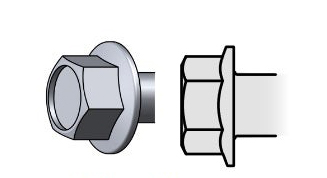

| Hex Washer Head | A hex washer head is essentially the same as the head style above, but includes a built in washer. These are common in the installation of gutters and siding. |

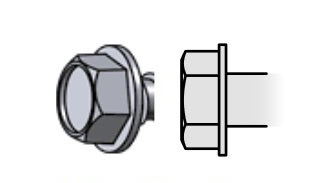

| Hex Flange Head | A hex head with a built in flange. These are extremely secure in that the flange can distribute pressure where the screw meets the surface. This spreading of the clamping load is a favorite in the automotive and construction industries. In fact, in bolt form this head type is used in auto and truck frames – some of the heaviest duty applications out there. |

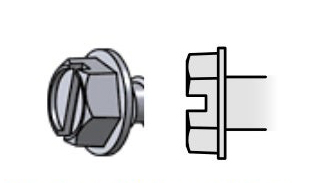

| Slotted Hex Washer Head | A hex head with a built in washer and a slot which provides an additional option for completing the fastening process. |

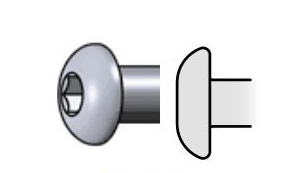

| Button Head | A low-profile rounded head using a socket drive which is tightened via an Allen wrench or hex key. These versatile and durable heads are used in automotive, electronics, machinery and manufacturing applications. |

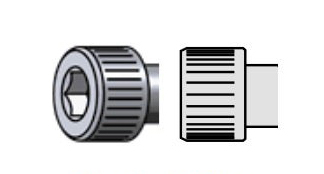

| Socket Cap Head | A small cylindrical head fastened using a socket drive. This head type is often found recessed within a counterbored hole. This leaves the head flush with the surface. |

Drive Types

NOTE: Like the head styles, many of these drive types are also known by their abbreviated terms in many circles. A Phillips drive is aka PH while a square drive can go by SQ or SD.

Ready to make a purchase to attach your fasteners? See

our full line of screwdrivers or search directly for one of our air, electric, manual and cordless options at your disposal to find the correct tool which will provide the consistent threaded fastening results you’ve become accustomed to receiving from ASG. If you have any questions about your fastener application, or need further assistance, please contact ASG Customer Service at 888-486-6163 or

[email protected].

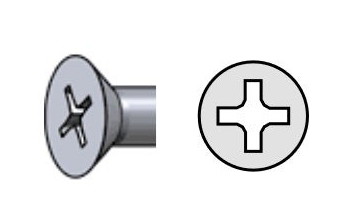

| Phillips & Frearson Drive | An X-shaped drive is the feature which sets these apart. The Phillips was originally designed to cam-out of the screw head seamlessly. The Frearson has a sharper tip and larger angle in the V-shape and is commonly used in marine applications. Also, one driver or bit can fit all Frearson screw sizes. |

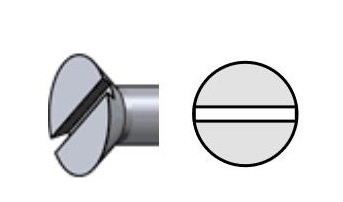

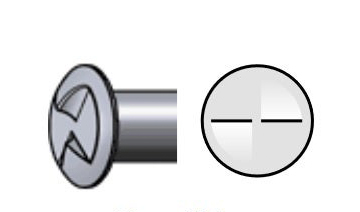

| Slotted Drive | A slot in the head for your standard-issue flathead screwdriver. |

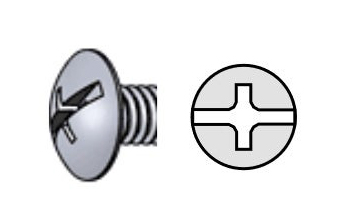

| Combination Drive | A combination of slotted and Phillips drives. |

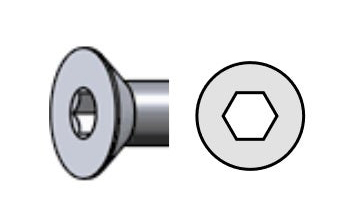

| Socket, Hex or Allen | A hexagonal hole for use with an Allen wrench or hex key. |

| One Way Drive | Installs with a normal slotted driver, but cannot be removed without special tools. |

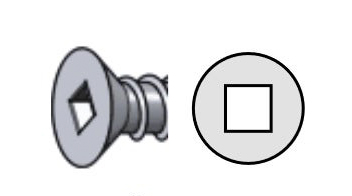

| Square Drive | Also known as Robertson drive, square drive, or socket head screws, these were invented by a Canadian travelling salesman in 1906. They are much less prone to cam-out as the driver can fit deeper into the screw head to prevent slippage. |

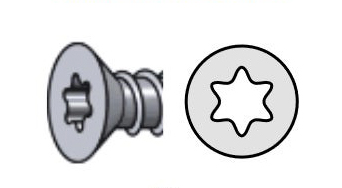

| Star Drive | A six-pointed star pattern specifically designed to prevent cam-out and stripped heads. These can actually handle more torque than square drive screws while also maintaining structural integrity better – which helps with removal. |