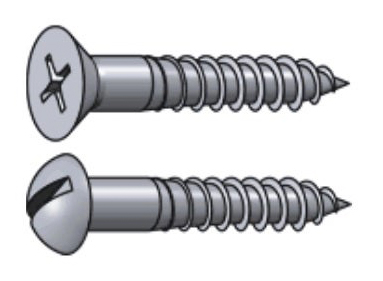

In this two part series we’re going to address each type of screw used in modern assembly, the head types, and the drive types. Below you’ll find a comprehensive list of each, but first, let’s go back in history:

Threaded Fastening Through the Years

Fasteners have been around since the first century B.C. when they were utilized in olive oil and wine production. The materials fasteners were made with graduated from wooden to metal in the 15th century to attach wooden stocks to the mechanicals of muskets.

The first patent on record for a screw came in 1760 and was shortly followed by mass production when Jesse Ramsden invented the first screw-cutting lathe.

As applications for screws increased, so did the types of screws being used in production work. We’ll provide more information on each type below, but for the most part the evolution of screw heads was to aid the assembly process by providing fasteners with non-slip qualities – which helped reduce operator fatigue and scrap while improving the overall consistency of fastening activities.

So, without further ado, let’s jump into the most common types of fasteners on the market today!

Types of Fasteners

Wood Screws | Wood screws have advanced quite a bit since debuting in the use of oil andgrape presses. Nowadays their primarily used in woodworking to draw twohalves of a joint together. What sets modern wood screws apart from thoseof the past are very tough shanks. |

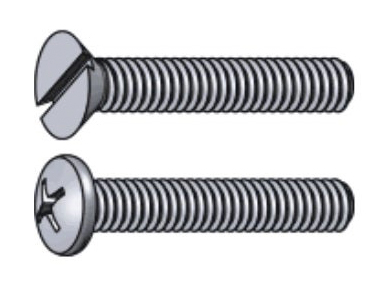

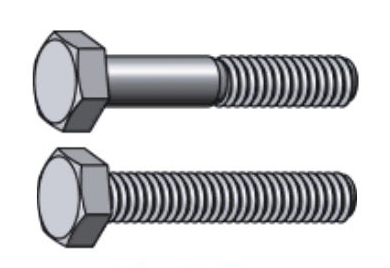

| Machine Screws

| Machine screws offer strength a wood screw cannot due to the sharpened (and more numerous) threads and are widely used in machinery and construction. Note the uniform diameter without the tapered pointed tip you’ll see in the next few examples. If the hole is tapped all the way through then a nut is attached to the end to complete the fastening. |

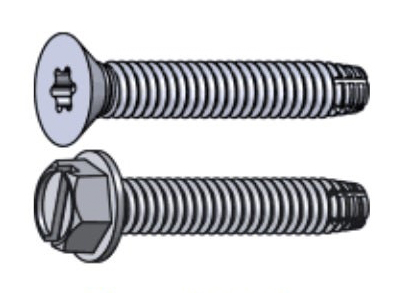

| Thread Cutting Machine Screws | Thread cutting machine screws have a bit of dual use in that they’re essentially self-tapping, can create threads, and more often than not they’re used as fasteners without a nut in applications which require maintenance. |

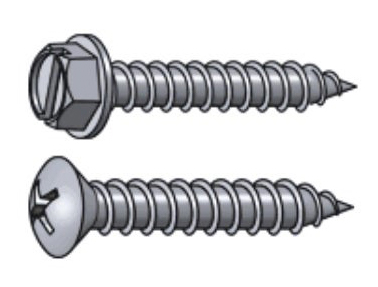

| Sheet Metal Screws | Sheet metal screws can be thought of as a hybrid of wood and machine screws. The pointed tip makes getting into sheet metal easy while the screw also has sharper and closer threads to its wood counterpart over the entire length of the screw. This is to ensure a proper seal. |

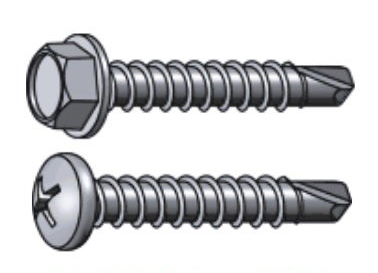

| Self Drilling SMS | Self drilling sheet metal screws are self-tapping just like the thread cutting machine screw mentioned above. In applications where finishing the fastening process with a nut is not possible, or again, the application requires periodic maintenance, these provide a solid alternative. |

| Hex Bolts | Hex bolts are basically a machine screw with a hexagonal head and are sometimes used with a nut to complete the fastening process. Used widely in automotive, construction and home improvement, hex bolts may be fully or partially threaded along the shaft. |

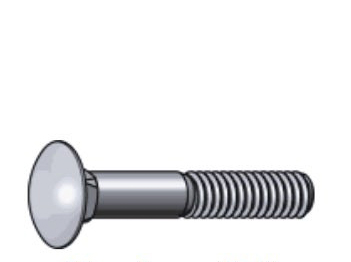

| Carriage/Plow Bolts | Carriage bolts were used widely in the 1800s in the construction of horse drawn carriages and are still commonly used to bare timber. The carriage bolt is squared under the head to make it self-locking when it is placed through a square hole in a metal strap. Since it is removeable from one side these are extremely popular options in the production of locks and hinges. |

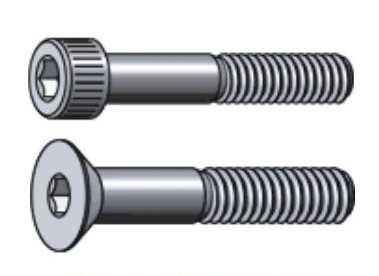

| Socket Screws | Socket screws are perfect for tight places where threaded fastening is needed. The hexagonal drive built into the head allows for tightening with an Allen wrench or hex key. These are found in many common applications due to their ease of use and ability to reduce damage to internal components. |

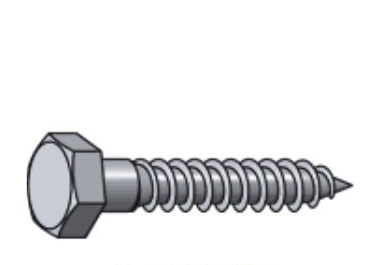

| Lag Bolts | Lag bolts are primarily used for high load timber applications despite being less strong than the carriage bolt. They are used in those applications, but moreso to reinforce and add strength. The pointed tip and hexagonal head make them a favorite in deck and rafter construction. |

| Shoulder Bolts | Shoulder bolts have a shank with a larger diameter underneath the head of the bolt, but further down the diameter shrinks for the threaded diameter. This change in diameter is what is known as the “shoulder” – allowing the threaded ability to rotate. |

If you have any questions about your fastener application, or need further assistance, please contact ASG Customer Service at 888-486-6163 or

[email protected].